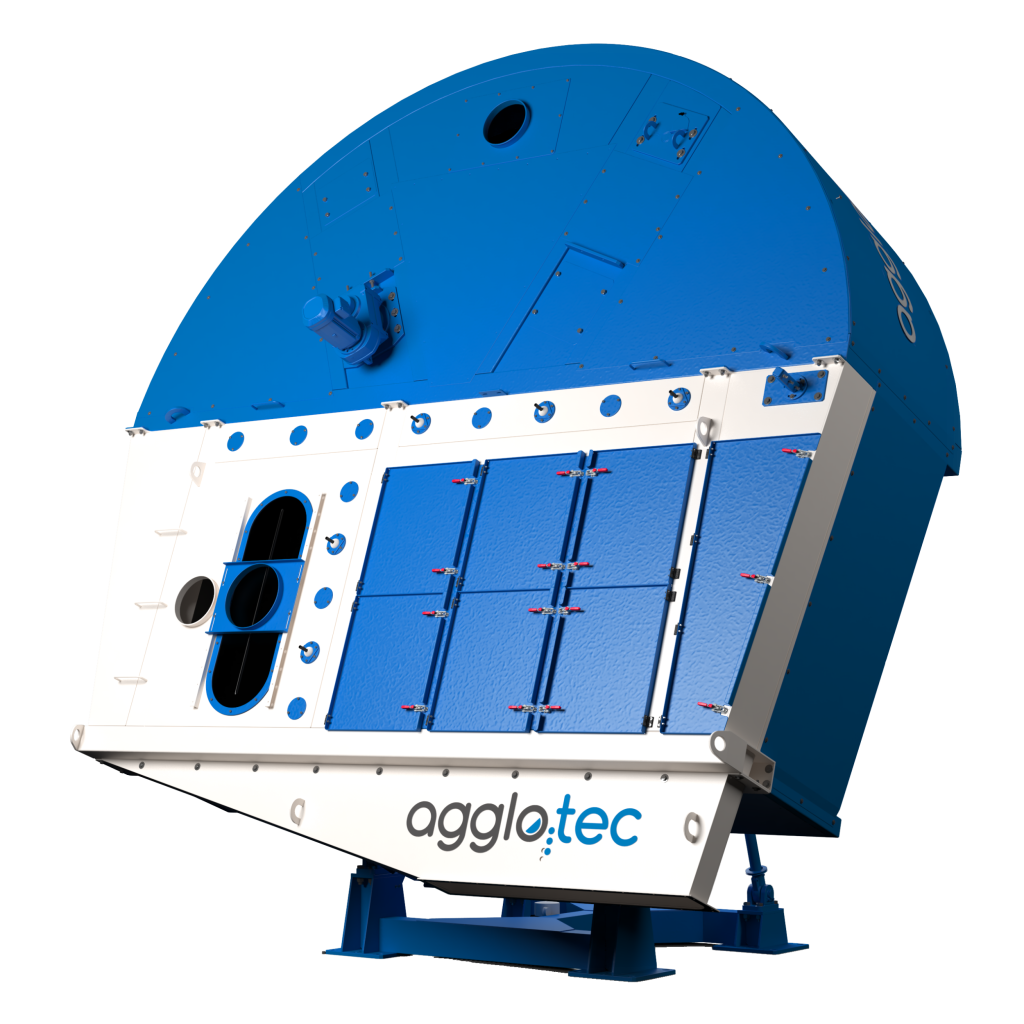

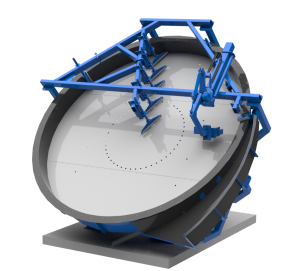

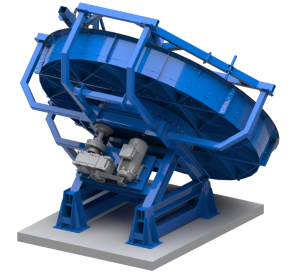

Pelletizing Discs

The AGGLOTEC pelletizing discs are driven by a central drive unit, whereby the rotating disc is mounted in a large-diameter antifriction bearing with approx. 1/3 of the disc diameter. This type of drive can be used for all machine sizes from Ø1,0m to Ø7,5m. Thanks to this design, the supporting structure has been optimised so that the rear of the machine, where the drive and bearing are located, is easily accessible for maintenance. Various different lining materials, scraper types and other accessories can be offered.

- Size Chart

Type code ø [mm] Height [mm] Lab-60×20 600 200 PPD-120×30 1.200 300 PPD-200×40 2.000 400 PPD-250×45 2.500 450 PPD-300×50 3.000 500 PPD-350×55 3.500 550 PPD-400×60 4.000 600 PPD-450×60 4.500 600 PPD-500×60 5.000 600 PPD-550×60 5.500 600 PPD-600×65 6.000 650 PPD-750×70 7.500 700 - Features

- open disc systems or completely covered for dust free operation

- various scraper designs

- angle adjustment

- robust bearing via slewing ring

- central drive unit and slewing bearing

- central lubrication unit

- durable and long lasting design

- maintenance friendly

- special features for special requirements

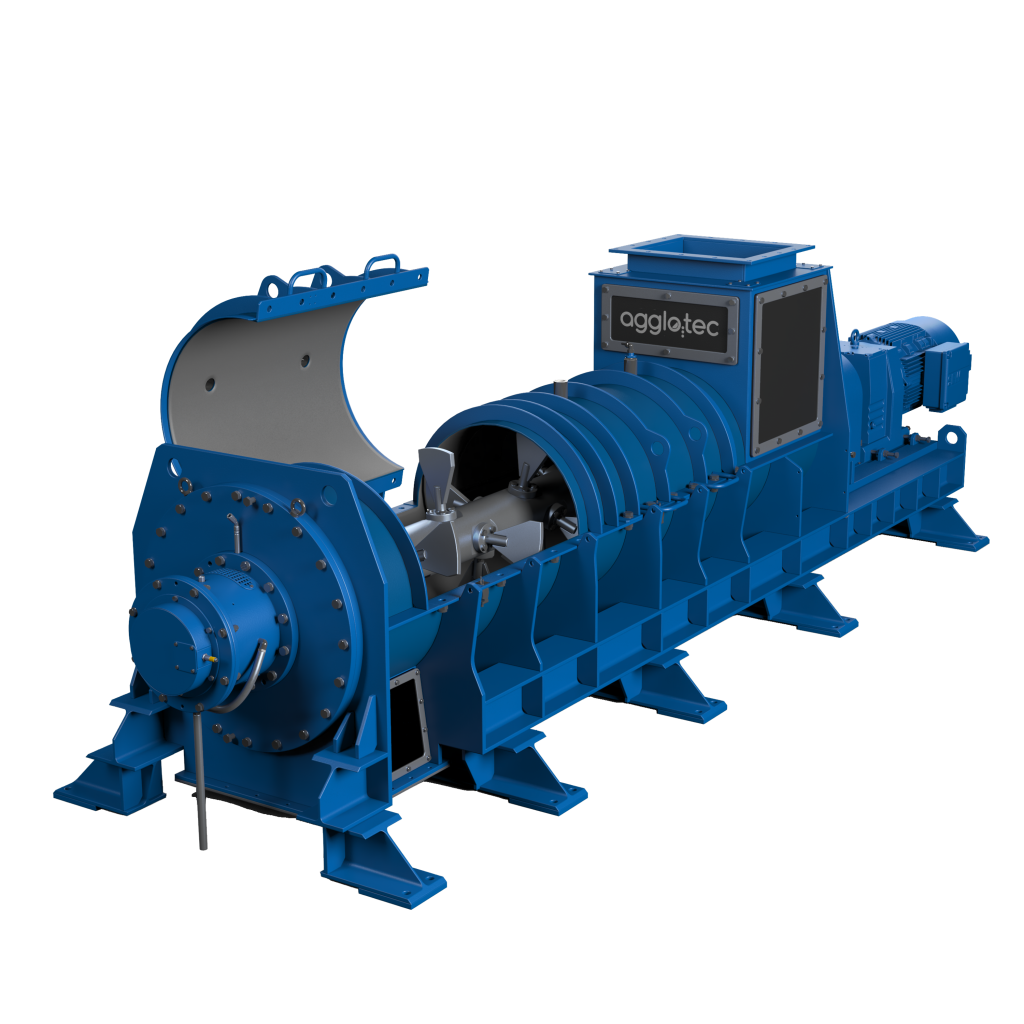

- Pictures

Mixers

AGGLOTEC mixers are mainly used for raw material mixing and pre-humidification / pre-granulation upstream the pelletizing disc. The retention time necessary to achieve the required mixing quality depends on the properties of the raw materials and can be determined in our pilot plant. The variety of different sizes and designs is also adapted to industrial mineral applications.

- Size Chart

Type code ø [mm] Length [mm] PMX-30×115 300 1.150 PMX-40×150 400 1.500 PMX-60×225 600 2.250 PMX-80×300 800 3.000 PMX-100×300 1.000 3.000 PMX-100×375 1.000 3.750 - More Details

-

In contrast to standard plough shear mixers, the high intensity model is characterized by a high specific power (kW/m³). Pelletizing of fine powders requires intensive agitation of solid matter, binding agent and water. Due to high turbulences inside the mixer, an optimized feeding material to the downstream pelletizing disc is guaranteed.

When configuring the mixer size according to product specifications, tests can be carried out in our in-house laboratory to ensure the correct process design and machine sizing.

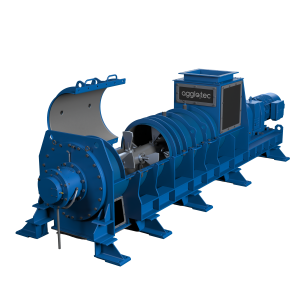

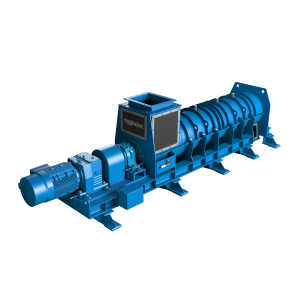

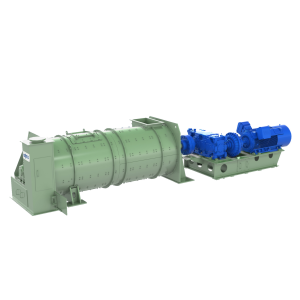

- Pictures

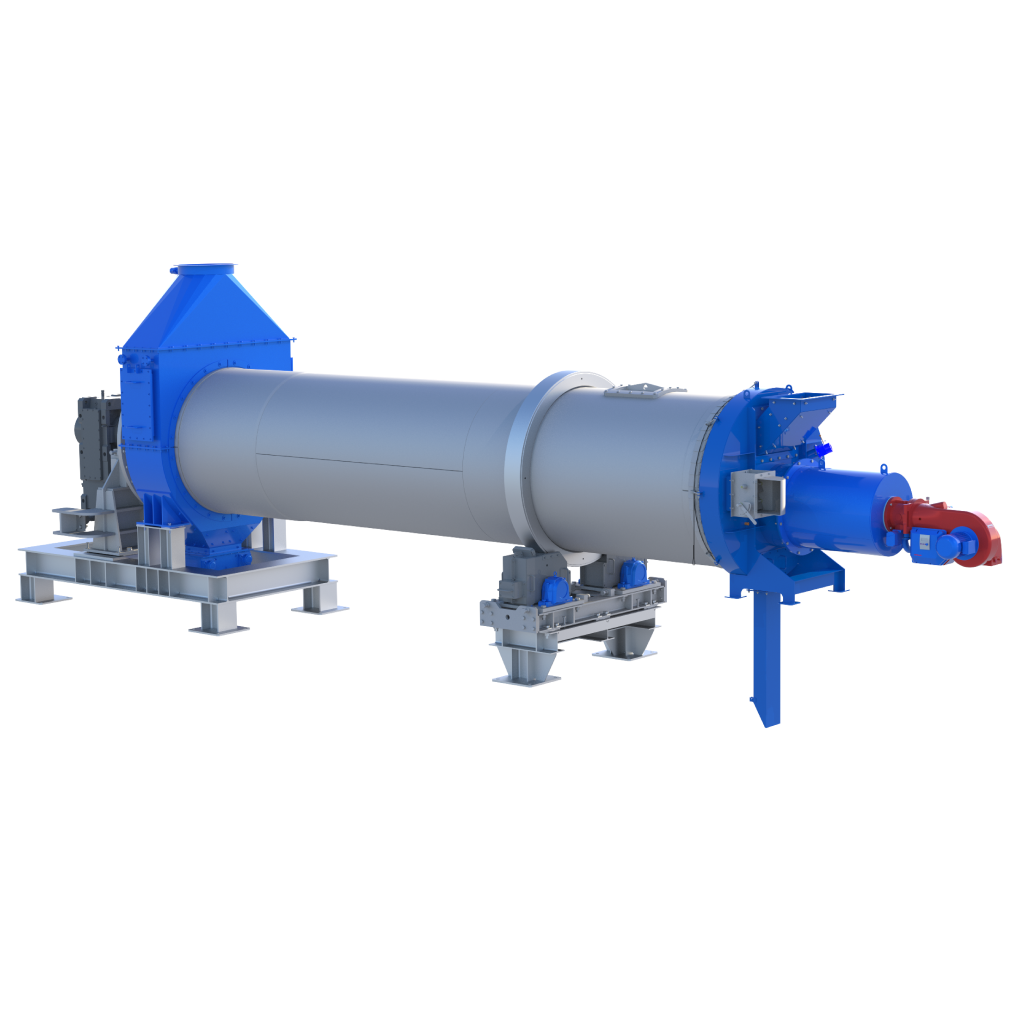

Dryers by

Drying is an elementary process step in the preparation of bulk materials and granules in all branches of industry. Either raw material streams have to be dried before they can be fed to downstream processes, or the green granules coming out of the granulating disc have to be dried in a gentle process to achieve the final strength and properties.

CEMTEC offers dryers and hot gas generators in various designs and sizes to meet customer requirements in tailor-made solutions.

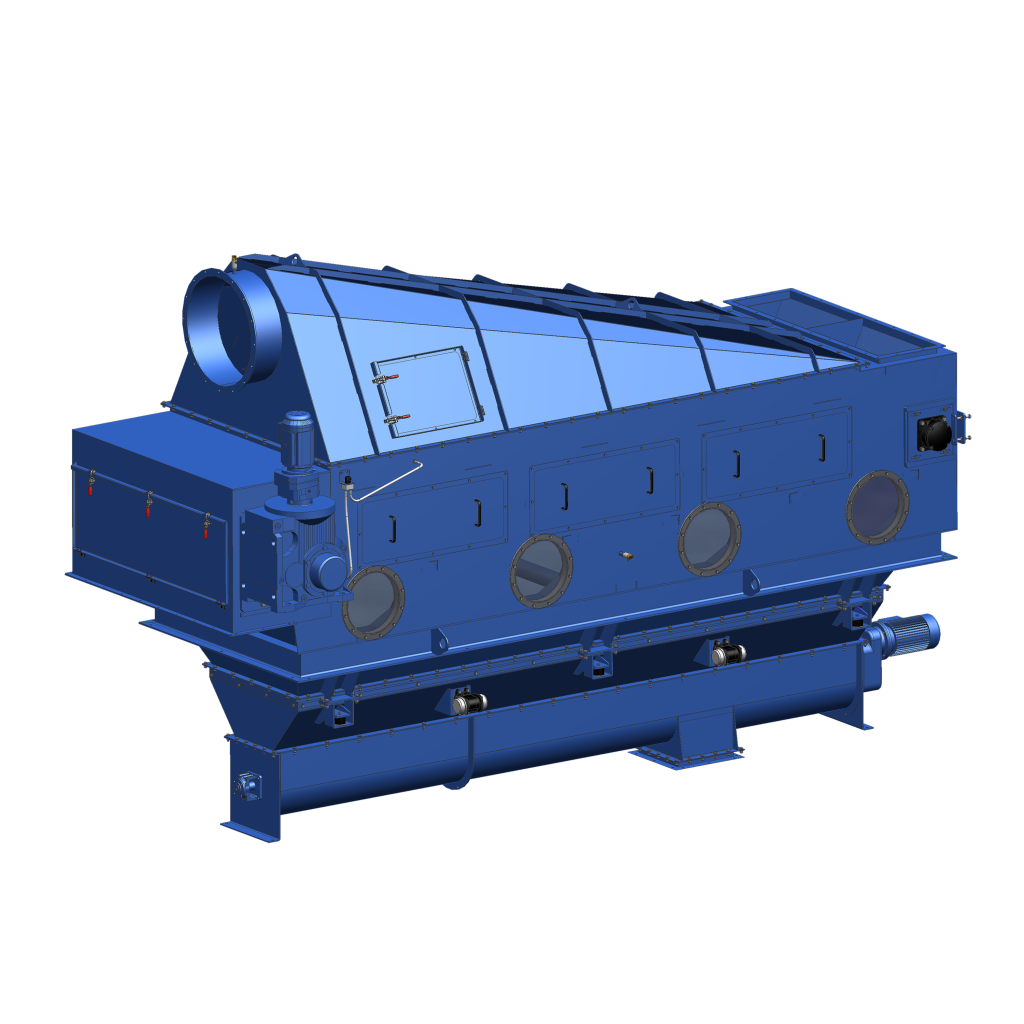

Coolers

Especially in the fertiliser industry, but not only there, it is important to obtain dry and stable granules. To achieve these specifications, it is important to control the product strength and temperature before the product is delivered from the dryer to the storage facilities. For this reason, AGGLOTEC supplies special floor cooling systems that are tuned for each process to achieve the required parameters.