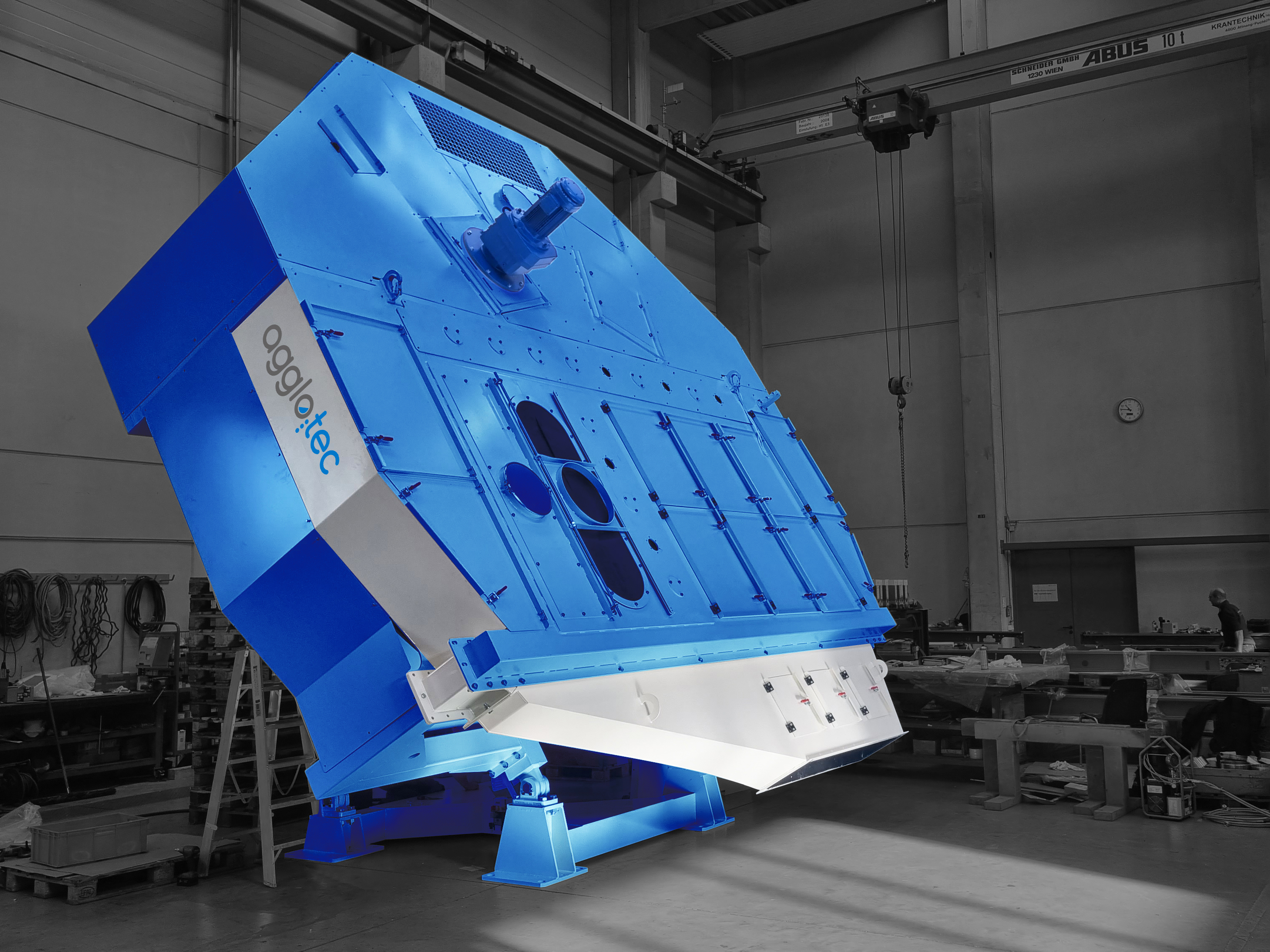

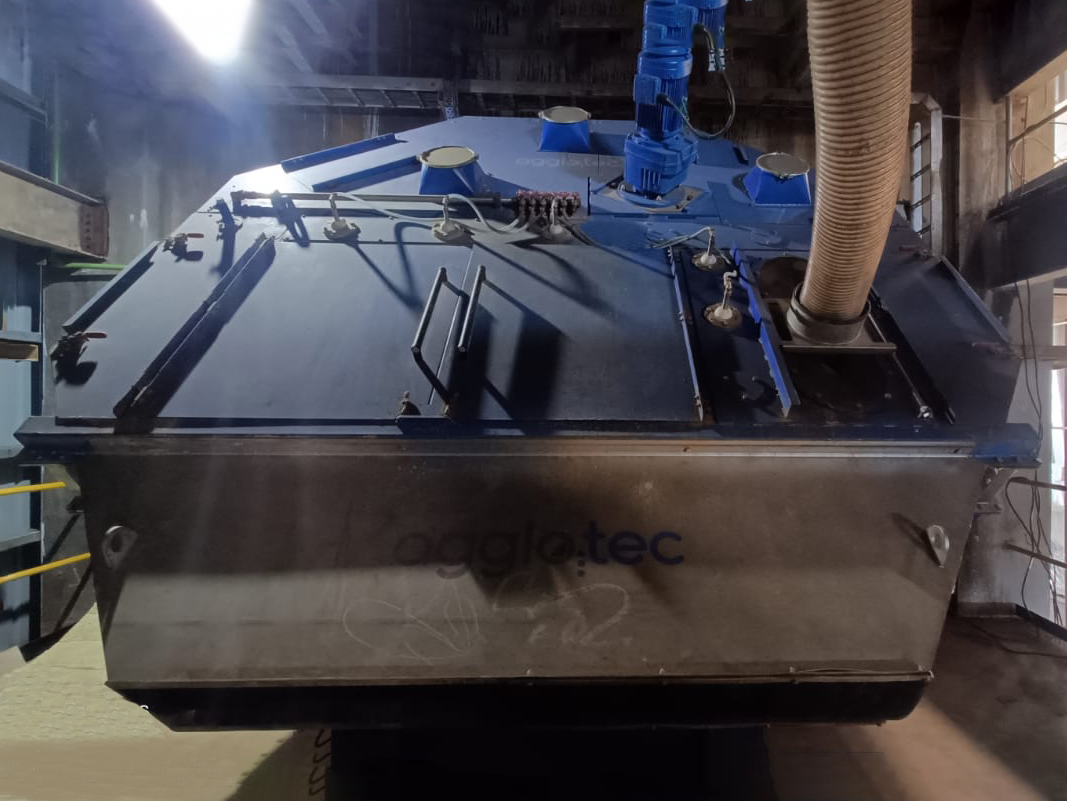

AGGLOTEC provides customized solutions, tailored to your processing requirements.

Agglomeration is a process that forms powdered raw materials into round pellets with a size of approx. 1mm to 20mm. Whether recycling materials, iron ore or fertilizers – the process to form powders into handable pieces is necessary for many reasons.

Our experience works for you

AGGLOTEC has access to expertise from 30 years of experience and a competence center with its own laboratory. We analyse and characterize your raw materials and make your product request to our challenge. Our customers are supported from the development phase of a project up until the commissioning of the completed facilities. We guarantee future production income. Piece by piece.

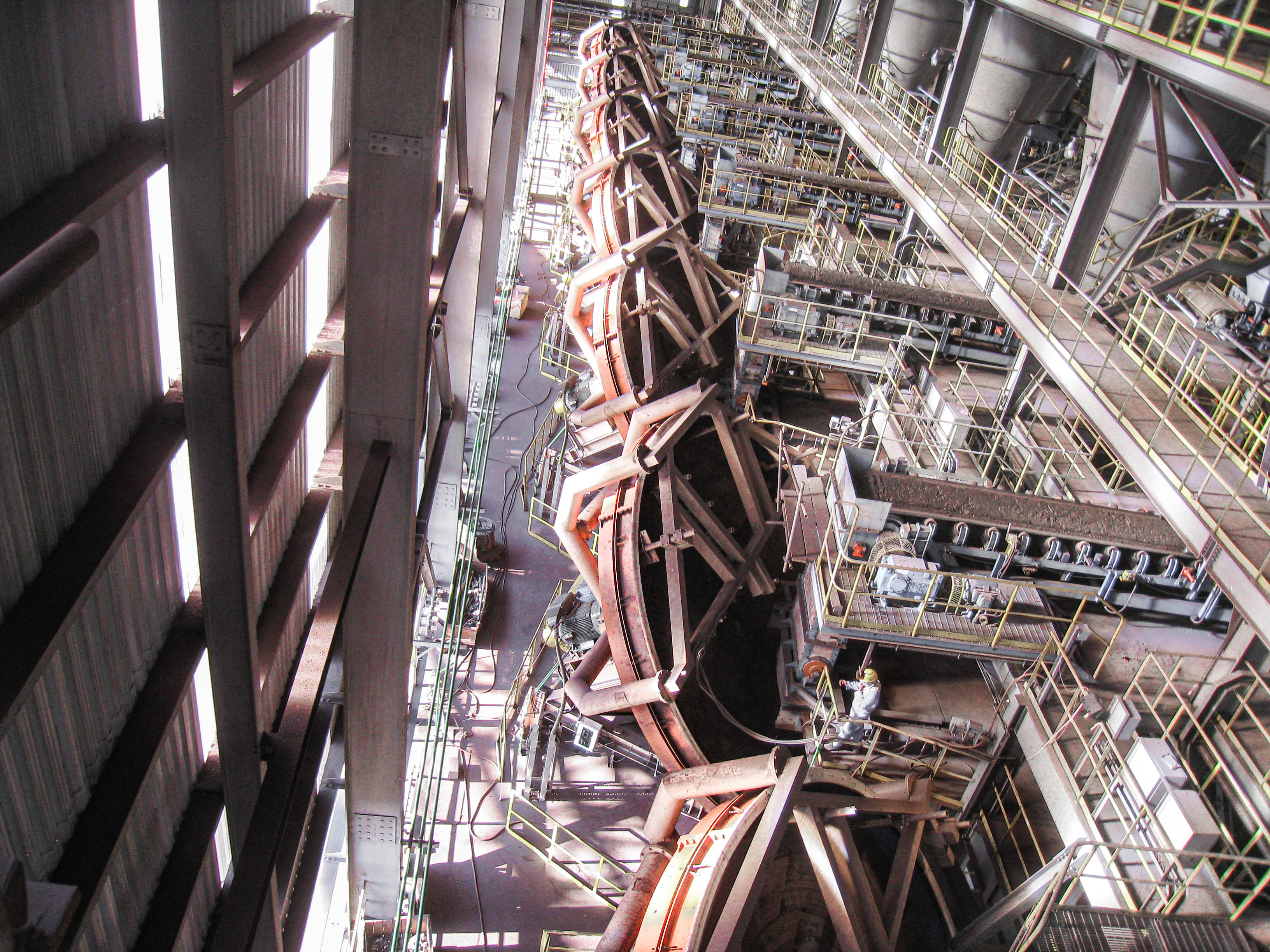

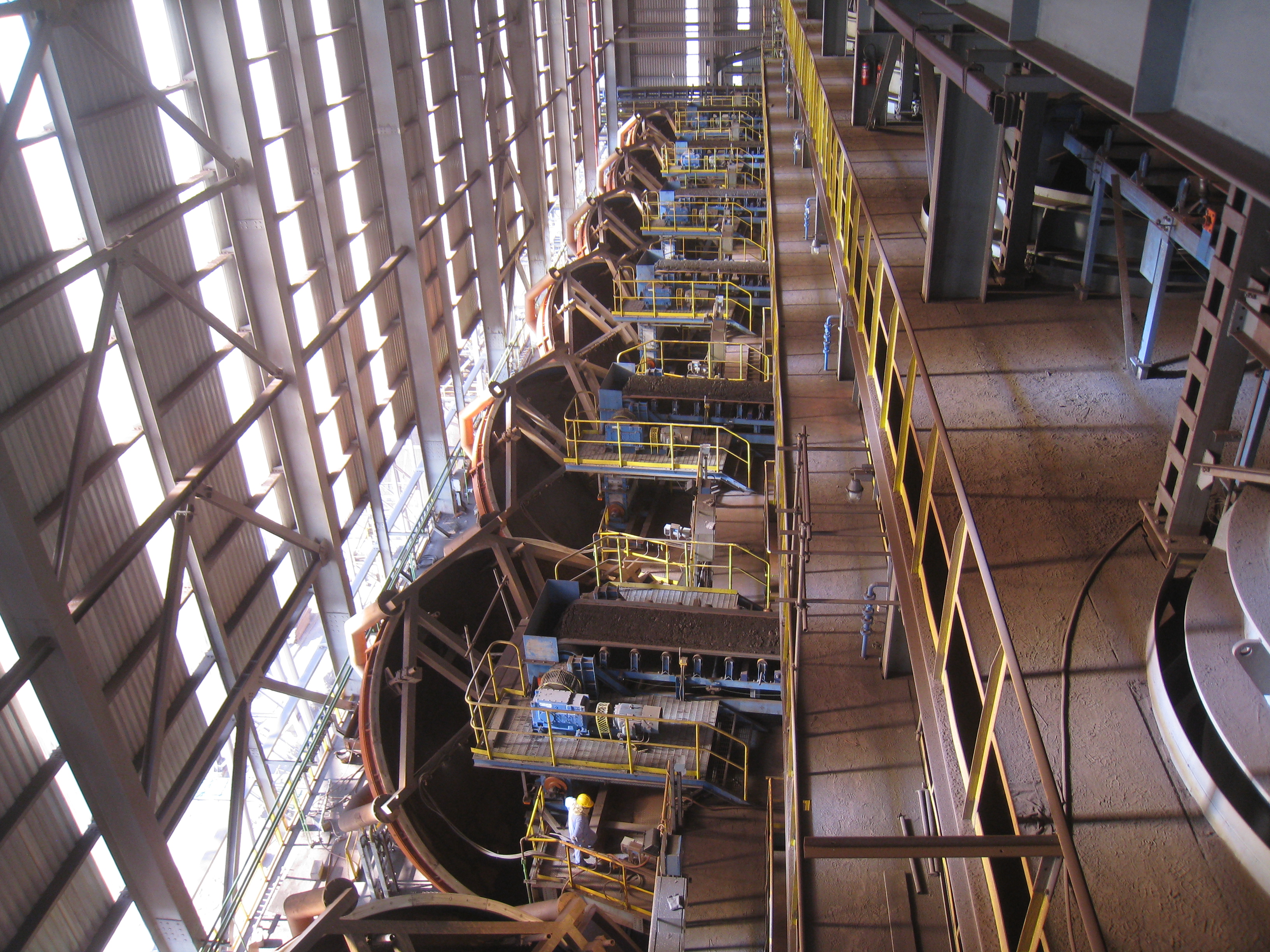

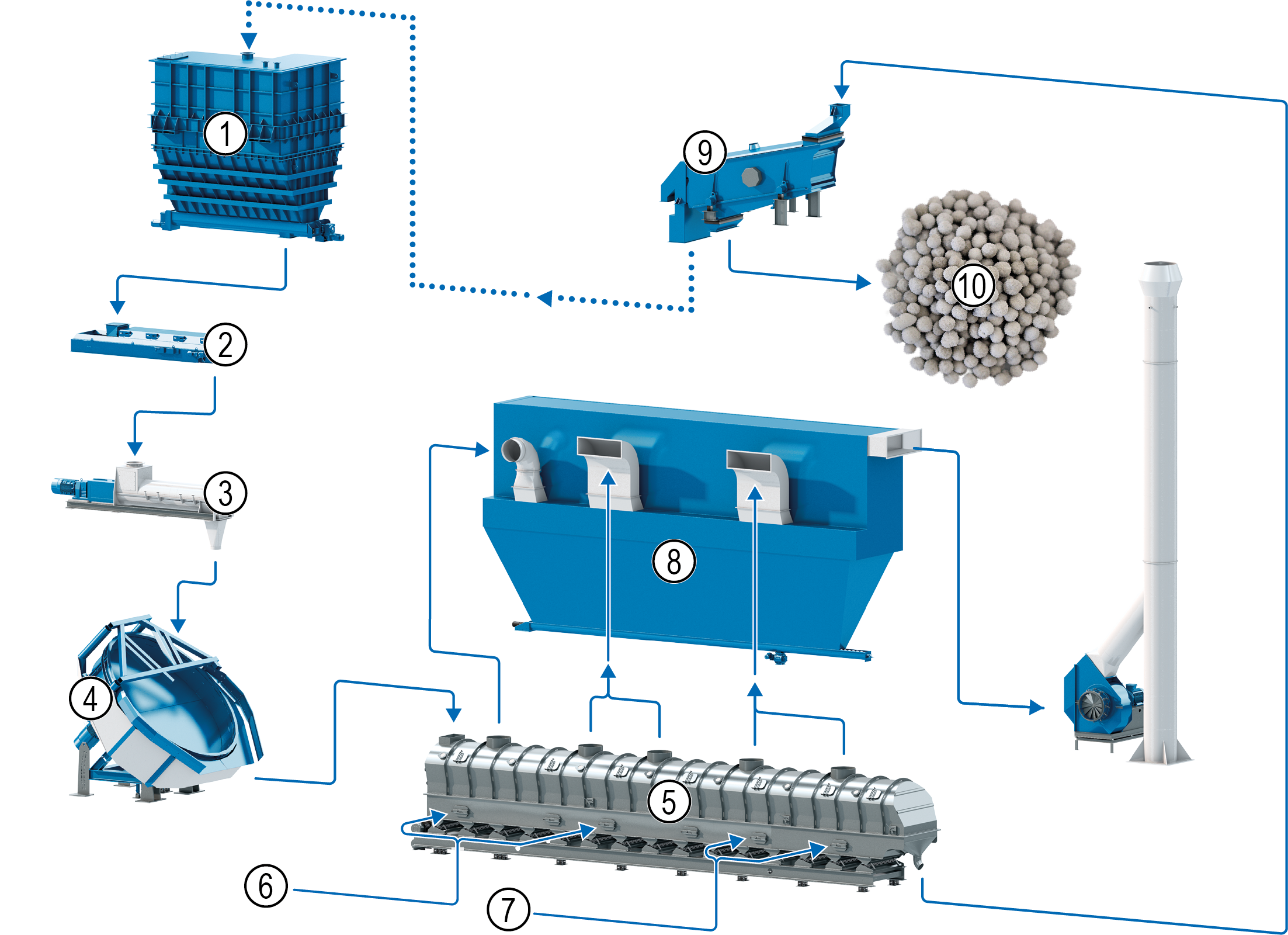

Typical Flowsheet for Mineral Granulation

| Pos | Designation |

|---|---|

| 1 | Feeding bin with discharge screw |

| 2 | Belt scale |

| 3 | Plough shear mixer |

| 4 | Pelletizing disc |

| 5 | Fluidized bed dryer (or other dryers) |

| 6 | Hot gas |

| 7 | Cooling air |

| 8 | Filter |

| 9 | Double deck screen |

| 10 | Product |

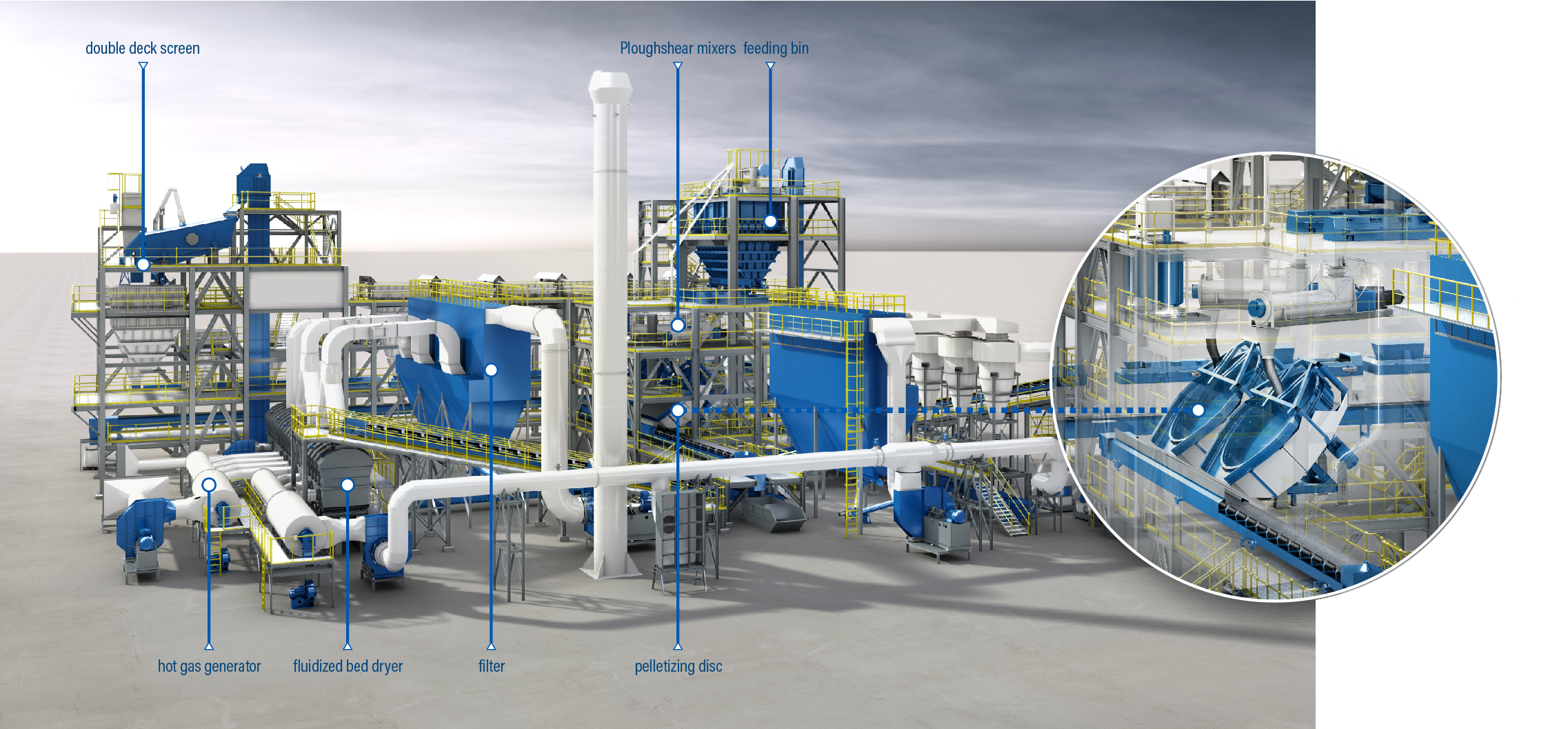

Mobile Plants

Our mobile plug-and-play plants are the perfect solution for granulation capacities of up to 4-5 t/h.

The fully functional plant consists of all necessary process steps from the raw material feed to the dried and packaged granulate including.

Branches

AGGLOTEC is the right partner for your agglomeration tasks in the various industries, whether as a supplier of highly efficient stand-alone machines or as a solution provider for complete processing plants.